Motorcycle excellence

Where design meets motorcycle performance excellence

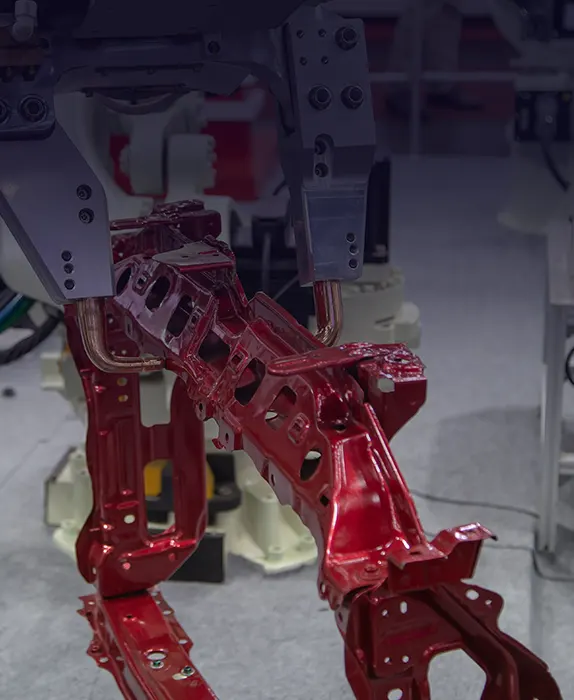

Advanced motorcycle fairing manufacturing methods

Iconic motorcycle brands and models

Legendary sportbike silhouettes define brand identity and distinguish flagship models across global markets today.

Heritage driven model lineups

Manufacturers refine model ranges to balance tradition innovation performance appealing loyal riders worldwide today globally.

Performance focused brand evolution

Each generation introduces engines electronics styling updates reflecting brand philosophy and responding to rider expectations worldwide.

Model differentiation and positioning

Distinct trims colors and specifications help buyers identify motorcycles matching experience budget and riding style.

Balancing performance aerodynamics and airflow efficiency

Workshop-ready reliability

Core motorcycle maintenance best practices

Effective cleaning for long-term durability

Soft brushes and cleaners protect paint surfaces during regular maintenance sessions.

Repairing small cracks before spreading

Specialized repair adhesives fuse damaged plastics securely ensuring lasting strength.

Reviving faded finishes and plastics

Professional polishing compounds restore color depth clarity and surface protection.

Protective coatings for durability

Advanced sealants shield panels from moisture dirt UV exposure damage.

Personalized design

Personalized aesthetics and custom graphics

Transforming appearance with vinyl wraps

Heat-activated vinyl conforms to complex curves, allowing for complete color changes without permanent paint. This method protects the underlying surface from scratches while offering limitless design possibilities.

Utilizing hydrographic printing methods

Water transfer printing applies intricate patterns like carbon fiber weave or camouflage to irregular shapes. The process involves dipping the fairing into a film suspended on water.

Compliance with road safety standards

Street-legal fairings must incorporate specific cutouts for headlights and turn signals to ensure visibility. Regulatory bodies dictate that bodywork cannot have sharp edges that pose risks to pedestrians during collisions. Reflective elements often integrate into the design for night safety, ensuring the motorcycle remains visible from all angles.

Track regulations differ significantly, often requiring a sealed belly pan to contain fluid leaks. These race-specific lower cowls prevent oil from spilling onto the asphalt, protecting other competitors from slippery hazards during high-speed cornering maneuvers. Scrutineers verify this containment capability before every race.